The Ultimate Guide to Acoustic Trickle Vents

Enhancing comfort through sound-attenuating ventilation

TABLE OF CONTENTS

The Ultimate Guide to Acoustic Trickle Vents

Table of Contents

- Introduction

- How airtight construction became a ventilation problem

- What are acoustic trickle vents?

- The need for acoustic ventilation is growing

- Building designers must navigate conflicting ventilation demands

- Understanding acoustic ventilation

- How can we be sure acoustic vents will work?

- Achieving Noise and Ventilation Compliance

- Acoustic vent performance metrics explained

- Steps for choosing the right acoustic vent for your project

- Guidance on specifying acoustic trickle vents

- How to choose the right acoustic vent supplier for your project

- Why Titon?

Introduction

In modern construction, balancing effective ventilation with noise reduction is critical. Acoustic trickle vents provide a simple solution, allowing fresh air to circulate while preventing noise intrusion.

They are a cost-effective way of satisfying increased occupant demand for quieter dwellings while meeting ever-tightening building regulations. Here’s everything you need to know about how they work - and how to procure them.

How airtight construction became a ventilation problem

The adoption of airtight building techniques in the construction industry from the 1980s onwards brought about an unexpected challenge for developers.

Improved building insulation and a lack of mandatory ventilation regimes led many new builds to develop serious issues with condensation, damp, and mould.

The resulting threat to occupant health led to the introduction of stricter ventilation standards in the revisions to Part F of England’s Building Regulations.

Since then, using standard trickle vents in doors and windows has become the most common and cost-effective solution for providing the background ventilation required by law.

What are trickle vents?

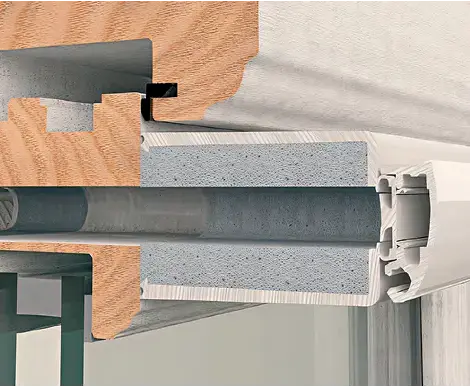

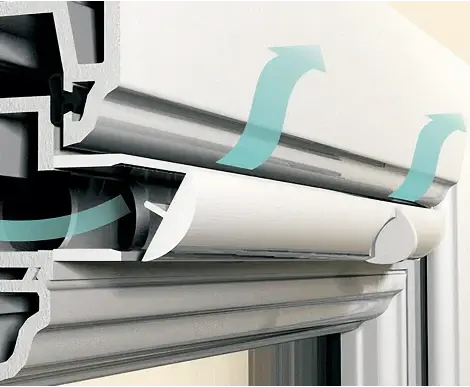

Trickle vents are slot-shaped devices in windows or door frames that provide natural, controlled background ventilation.

They allow a ‘trickle’ of fresh air to flow in when windows and doors are closed. Trickle vents can be fitted in PVCu, aluminium, vinyl or timber frames and sashes, according to the needs of the manufacturer or home-owner.

Standard trickle vents - where are they found, and what do they do?

- Located at the top of frames or sashes

- Manual open/close operation

- Cover 2000-8000mm² ventilation area

The need for acoustic ventilation is growing

While trickle vents successfully bring fresh air into properties, their introduction inevitably increases the risk of unwelcome external noise leaking into interiors.

And with the rise of denser urban housing developments, this has become an increasing problem.

Source: London Plan Review 2024

Building designers must navigate conflicting ventilation demands

Sound attenuation has become a significant issue for occupants battling rising noise levels from nearby roads, flight paths, entertainment and transport hubs.

But the need for noise mitigation must be balanced with the need for proper ventilation.

ENERGY EFFICIENCY

- Airtight construction for heat retention

- Reduced energy consumption

- Lower carbon footprint

HEALTHY INDOOR ENVIRONMENT

- Sufficient background ventilation

- Humidity control

- Prevention of condensation and mould

Acoustic Comfort

- Protection from different types of external noise: Roads, transport hubs, flight paths, nightlife

Understanding acoustic ventilation

What are acoustic trickle vents?

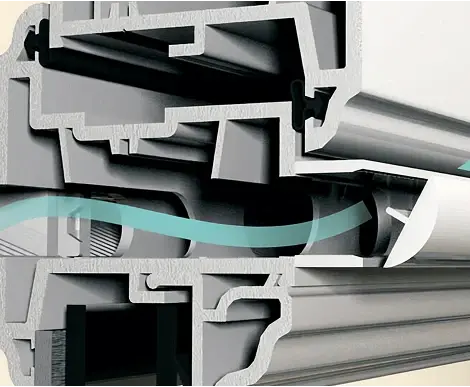

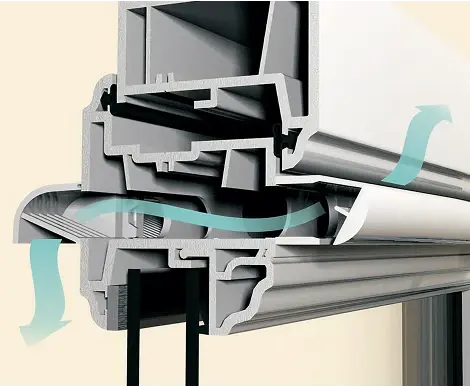

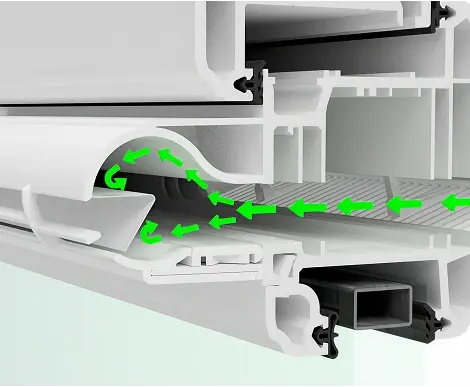

Acoustic trickle vents are specialised ventilation devices designed to allow the flow of fresh air into indoor spaces while minimising the transmission of external noise. Acoustic trickle vents look and work like standard trickle vents, but have more complex internal designs that attenuate noise more effectively.

Inside an acoustic trickle vent - how do they work?

-

Local planning laws may impose additional requirements for acceptable interior noise levels based on a development's specific location and context.

-

These materials disrupt and dampen sound waves as they pass through the vent, reducing noise levels.

-

The vents often incorporate a complex internal structure that forces sound waves to travel through multiple chambers or turns.

-

This design dissipates energy from the sound waves, making them less audible indoors.

-

Acoustic solutions may require dual combinations of a vent inside a door or window and a canopy outside to minimise noise transmission.

-

The vents maintain equivalent airflow areas (e.g., 2500mm² to 5000mm² EA) while controlling noise ingress.

-

High-performing gaskets improve sealing against adverse weather and enhance the vent’s acoustic efficiency, particularly when closed, decisively blocking external noise.

How can we be sure acoustic vents will work?

What are acoustic trickle vents?

Confidence in acoustic ventilation performance requires rigorous testing under standardised conditions.

The standard BS EN ISO 10140-2:2021 provides the framework for laboratory sound measurements.

Laboratory testing of acoustic vents should occur in controlled environments, measuring sound reduction across frequencies from 100Hz to 5000Hz.

This tells manufacturers how vents perform under ideal conditions. Field testing then validates this performance in real-world installations, considering actual background noise and installation variables.

Achieving noise and ventilation compliance

Planning Laws, Building Standards, and Regulations?

The UK Approved Document F outlines the requirements for effective ventilation in internal spaces based on an Equivalent Area (EA) rating. EA quantifies the size of an opening necessary to achieve adequate airflow, ensuring air quality.

Approved Document E specifies the minimum sound insulation standards that new building projects and renovations must meet to protect occupants from noise.

Additionally, Approved Document O focuses on mitigating overheating risks in residential properties. It mandates that ventilation strategies improve air quality and prevent excessive heat buildup, particularly in urban developments or properties with large glazed areas. Other standards and guidelines play a crucial role in addressing noise attenuation:

- The World Health Organization (WHO) defines noise levels above 65 dB as noise pollution.

- In residential developments, BS 8233:2014 recommends:

- Noise levels in habitable rooms should not exceed 35 dB.

- Restful sleep is only achievable when ambient noise levels remain below 30 dB.

- Local planning laws may impose additional requirements for acceptable interior noise levels based on a development's specific location and context.

- Minimum EA requirements: 8000mm² for habitable rooms and kitchens and 4000mm² for bathrooms.

- The need for adequate acoustic performance to meet noise insulation requirements.

Resources

Quiet. Compliant. Perfect fit.

Discover Titon's range of acoustic trickle vents for your next project!

Acoustic vent performance metrics explained

The acoustic performance of vents is expressed in a decibel (dB) rating derived from the Dn,e, and w values (which stands for element-normalized level difference, weighted). This single-number rating indicates the overall acoustic performance of a vent across various frequencies.

Interpreting Dn,e,w Values

- Higher Dn,e,w values indicate better sound reduction performance.

- The rating is typically expressed in decibels (dB).

- For example, a vent with a Dn,e,w rating of 44 dB would provide better sound attenuation than one rated at 35 dB.

Steps for choosing the right acoustic vent for your project

1

conduct an acoustic survey

If you’re applying for planning permission to create, extend or alter a residential dwelling near a source of noise (e.g. traffic, rail or industrial noise), then it’s likely that you’ll require a residential noise survey to support your planning application and define your noise attenuation strategy.

2

DEFINE PERFORMANCE TARGETS

Determine required sound attenuation levels based on survey results.

3

Collaboration with Experts

Work with acoustic and ventilation specialists to consider appropriate solutions given the regulation, building type and setting.

4

Select Compliant Products

Choose vents that meet acoustic and ventilation standards, as well as any aesthetic requirements.

When selecting an acoustic vent, review frequency response charts provided by manufacturers. These charts reveal how effectively the vent handles specific noise types, offering more practical insights than a single overall rating.

Guidance on specifying acoustic trickle vents

Slot sizes and canopy combinations

Acoustic trickle vents are specialised ventilation devices designed to allow the flow of fresh air into indoor spaces while minimising the transmission of external noise. Acoustic trickle vents look and work like standard trickle vents, but have more complex internal designs that attenuate noise more effectively.

- Consider vent and canopy combinations: Manufacturers offer various inner (ventilator) and outer (canopy) size combinations to achieve the required EA value.

- Match to window types: Ensure the chosen vent colour and finish is compatible with the window aesthetic - this may be especially important in high-end developments or in listed buildings.

- We recommend aluminium vents for maximum durability.

How to choose the right acoustic vent supplier for your project

Selecting the right acoustic vent supplier is critical to ensuring compliance, performance, and long-term value in your project. With the growing importance of noise control and energy efficiency, partnering with a supplier that can meet your technical and regulatory needs is essential.

Here’s what to look for when choosing an acoustic vent supplier.

A reliable supplier will offer products that fully comply with UK Building Regulations, including:

-

Part F: Adequate background ventilation to improve air quality.

Part E: Acoustic insulation standards to reduce noise intrusion.

Part O: Overheating mitigation in residential properties.

Why it matters:

Compliance ensures your project meets legal requirements and avoids costly reworks or delays.

A dependable supplier should provide the following:

-

Technical guidance to help match vents to environmental and acoustic needs.

Detailed installation manuals and on-demand advice.

Customisation options such as colour finish

In-house or third-party testing and certification.

Why it matters:

Expert support simplifies the process, reduces errors, and ensures optimal performance and compliance.

Look for suppliers investing in research and development to deliver cutting-edge solutions, such as:

-

Enhanced noise attenuation for urban and high-traffic areas.

Energy-efficient designs to support ventilation in airtight construction.

Vents that address evolving regulatory and environmental demands.

Why it matters:

Innovative products provide long-term benefits and keep your projects competitive.

Choose a supplier with a proven track record for:

-

Consistent product availability and timely deliveries.

Clear warranties that protect your investment.

Why it matters:

Reliable supply chains help meet tight project timelines and provide assurance of product quality.

Why Titon?

Comprehensive technical support, regulatory guidance, UK manufacture, and a strong supply chain make Titon a trusted partner for developers, fabricators, and contractors.

For tailored advice and reliable solutions, contact Titon to explore our range of acoustic vents and ensure your project achieves the perfect balance of ventilation and noise control.

Titon excels in delivering high-performance acoustic ventilation solutions tailored to meet industry demands. Titon’sSF Xtra Sound Attenuator combines compliance, noise reduction, and energy efficiency.